Well the ECU is fitted (May) and finally got it to a point of starting the car.....Plenty of head scratching with the wiring, but that was me trying to splice into the old loom.

Mini USB fits nicely. But you must use the one supplied or one that's well shielded and is wired through a magic plastic bottle cork thingy!....Otherwise you get connection drop-out from interference.

As its laptop based now and I opted for USB connection its quite amazing how many settings there are! MS2 can be used for any engine, 4 pot, V6, V8, V12..... You need to set everything to match your system and calibrate sensors & injectors. You need to have some idea about AFR, fuelling ratios and ignition advance as mine were all way off out of the box!

Each dial is configurable to whatever info you want to see. and there are different screen layouts to tinker with.

My brain is being fried even more now. And now engine wouldn't start!

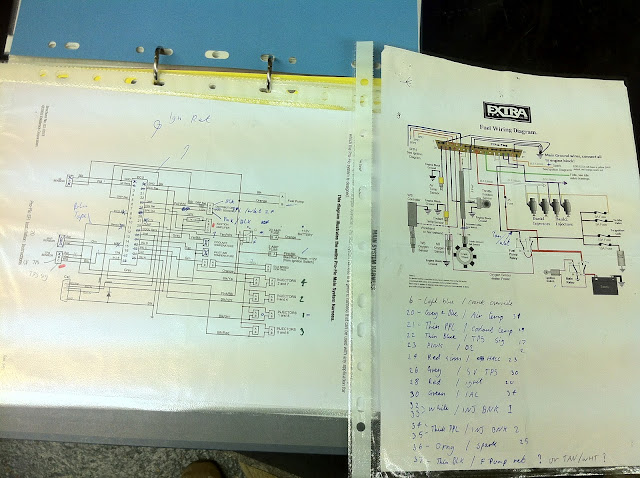

One thing that I found frustrating it that lots of instructions online are

based on using the Megatune software. I spent a long time reading these

while waiting for my ECU to be made. When it came, it uses another

program called TunerStudio and said MS2 Extra isn't compatible with

Megatune..... great!

Much superior apparently but completely threw me

and I lost enthusiasm to try and reinterpret the 2 different settings.

Tony M from the cobra club was kind enough to come down and try to get me running as something didn't like me. It turned out it didn't like him either, lol, sadly there was something underlying that we couldn't find. It would start and then die after 5 seconds! So back to the drawing board.

I got back in contact with Phil who built the ECU (Backup I wouldn't have had doing a DIY ECU!) and he was very helpful in trying to get me started

It turned out I had 2 components used from the last ECU that didn't like my new setup amongst me not understanding some of the instructions.

Hall effect sensor in the dizzy, and my ignition amplifier.

A

few wrong settings in the software and it didn't like these. I also

managed to cook my ignition amp while confusing myself with 2 wiring

diagrams. With both of these sorted, VR sensor in dizzy replaced the Hall sensor and a new amp. I got in touch with a chap who tunes MegaSquirt professionally!

http://www.v8developments.co.uk/

Something I hadn't found for ProFlo!!!

Once I had fixed the bits and corrected some settings, we got the car running after 2 emails!

The first couple of runs threw up another problem. above 50% throttle,

the engine would buck and then die.... Both Phil and Shaun thought it

was a power issue to injectors or coil, or even a bad ground. Quite a

few checks later I eliminated it being the ground, added a shielded wire

to the VR loom (reduce possible interference, and checked injector

power with a bulb that was indicated they were firing just after engine

died. On a data log it was recorded as I slowly accelerated that it was

over fuelling so much that it killed the spark!!! So Some more

adjustments by Shaun were made to lean it out a little......

The beauty of MegaSquirt is once its running, you can do a data log and email it. Shaun the chap who has been helping me has done so via emails. I data log a run, send it to him, he changes a few things, sends it back and I log another run and so on.... Just got to wait for some dry roads as the runs I need to do, are to hold the revs at say 1500rpm with the brake pedal and give it full throttle for a few seconds, try and do this at varying RPM's and also again at 50% throttle.

Now its still pissing with rain, I'll have to wait for some dry roads! WOT + Brake pedal = !!!!